|

|

|

|

|

|

| The New Venture Series ME4 Production Work Cell features automated loading and unloading of the sheet materials. |

| Venture Series Model - ME4 The Excitech-USA Venture ME4 work cell is designed with the high production cabinet shop in mind. The customer is able to streamline the material handling, CNC routing, and offloading operations, seamlessly and efficiently. The Excitech-USA CNC System is G-Code based and compatible with Cabinet Vision and other standard cabinet design programs. |

|

| Here's how it works: The Excitech-USA Venture ME4 work cell will automatically load a 4x8 sheet from a pallet by way of a scissor lift located at the rear of the CNC machine and a movable gantry system equipped with suction cups. The material sheet is safely and accurately guided onto the CNC platform by the gantry using retractable guide rails and stops on the table. Once the sheet is placed, the operator turns on the vacuum hold down and starts the cut cycle for the CNC to execute. After the sheet is fully processed, it is then pushed off to a conveyor table at the front end while another sheet is simultaneuosly loaded from the rear of the machine again. During this whole process the residual dust, that is not picked up from the dust collector, is swept off the table and conveyor into various chutes keeping the work cell clear of dust and debris. Upon completion, the individual parts are labeled by the operator through an integrated barcode system. This facilitates clear identification of the finished parts for quick and easy assembly later on. | |||||||||||||||||||||||||||||||||||||||

|

ME4

Construction Features

|

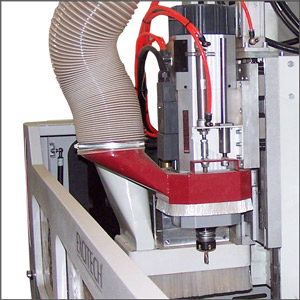

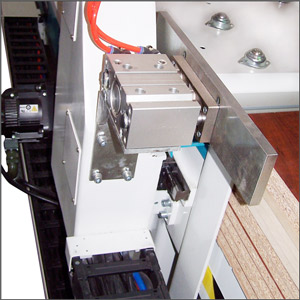

Spindle The Venture Series ME4 Production work cell comes standard with a 12HP HSD high frequency automatic tool changer. This precision spindle requires no maintenance, uses industry standard ER collets and ISO 30 tool holders. Fully programmable speeds from 6000 to 24000 RPM, and comes complete with pneumatically retractable vacuum hood. |

|

Base Frame All frames are designed using state-of-the-art CAD/CAM software which analyze stresses applied to the frame’s structure, also known as Finite element analysis. This state-of-the-art leading edge technology assures the support foundation is structurally stable that will last the test of time. Each frame is stress relieved assuring long term stability in the frame structure mechanics. |

|

Gantry The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady firm beam assembly. This quality engineering and workmanship result in smooth precision cutting. |

|

Gantry Support (Uprights) The Gantry uprights are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, and wiring harnesses. |

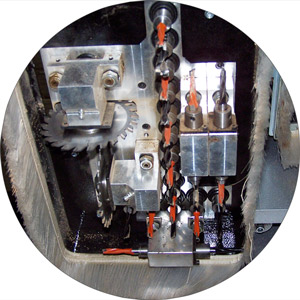

| 8 Tool Rotary Carousel ME4 Production work cell includes an 8-position rotary carousel that moves with the machine while the gantry travels. The use of a carousel speeds up tool changes assuring faster cycle times increasing production capability. |

|

Fam Drill Bank or |

|

|

Linear Racks The Venture Series ME4 Production work cell uses precision Helical gear racks on the X- and Y-axes. The use of Helical precision rack n pinion assures smooth precision cutting at high feed rates. In addition, the method in which the racks are mounted help reduce maintenance. |

|

Drive Motors The New Venture Series ME4 Production work cell utilizes high-powered AC Servo motors powered by Delta Drives. These motors are brushless, therefore, requiring no regular maintenance, thus, reducing any maintenance downtime. |

|

Drive Train Assembly The XY Drives include a precision gearbox which is directly coupled to the Servo motor and pinion. This eliminates belt stretch inaccuracies assuring high-speed machining while the system positions the spindle accurately. |

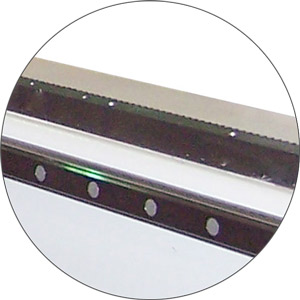

| Bearings THK HSR bearings and rails are used on all three axes. These superior quality components complement the overall construction by providing smooth play-free motion. This results in superior cut quality, requires minimal maintenance, and increases the machines longevity. |

|

|

Material Alignment System - Pusher Bar Venture Series Model - ME4 Production work cell machine comes standard with a material alignment system. The material is centrally aligned with the machine's origin assuring the operator does not have any intervention with realigning the machine's start origin point. |

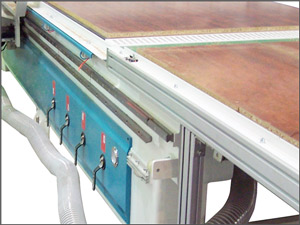

| Material Alignment System - Pop-up Side Rails The pop up side rails keep the previous routed nest uniform as the material is pushed onto the conveyor. |

|

|

Suction Cup Load System The rear suction cup load system attached to the Venture ME4 gantry can easily load a sheet on to the bed surface. As it loads, it automatically sweeps the deck clean of any debris assuring a clean scavenger board surface for maximum vacuum hold down as it processes each and every sheet. |

|

Rear Scissor Lift The automation work cell includes a rear scissor lift which supports and raises the stack of material to the machine's vacuum bed height, which is monitored with optical eye-sensing stack material height and machine bed surface. |

|

Vacuum Table The vacuum plenum table surface is multi-zoned which allows the operator to easily switch from full sheet processing to smaller part processing, (which requires a smaller segmented area). Zones can be turned off easily via control valves on the side of the machine. |

|

Safety Enclosure Safety enclosure prevents any flying debris from exciting cut area. |

|

Dust Extraction System A single overhead central dust extraction manifold prevents flexible hose lines from getting hung up on the moving parts preventing damage. |

|

Conveyor Table Conveyor table is located at the front end of the machine. |

|

Down Draft Vacuum Troughs The machine is equipped with various downdraft vacuum troughs which collect falling chips and dust as the routed sheet exits the machine bed. |

|

Vacuum Pump Comes standard with motor starter, vacuum gauge, primary and secondary filter, check valve and all necessary plumbing to connect to router |

|

Bar code printer and scanner (Optional) |

|

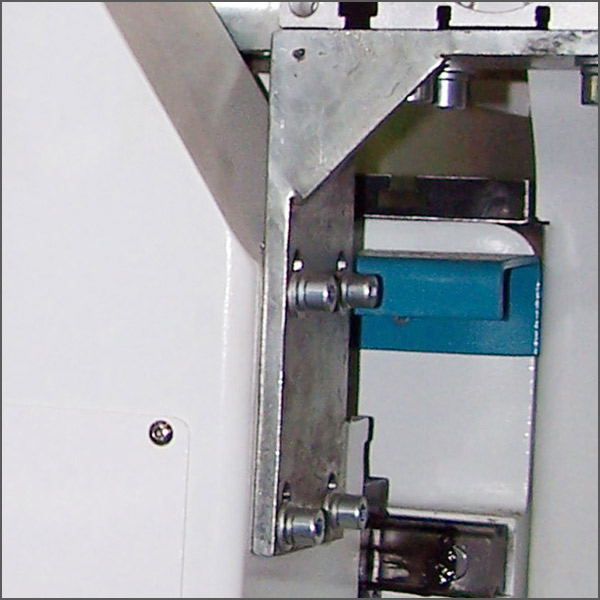

Electronics All the electrical components are housed and wired in a doubled-doored Nema 4 electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet. In addition, the cabinet serves as a work bench for the tools required. |

|

Hand-held Pulse Generator The hand-held pulse generator allows the operator to maneuver around when setting up tooling. |

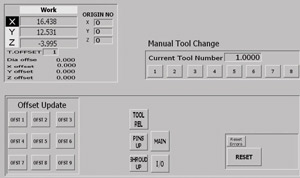

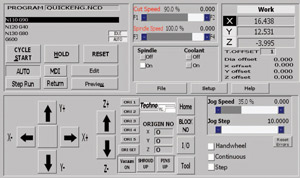

| CNC Windows-Based G-Code Interface is included with each Venture Series ME4 Production work cell machine and is an indispensable tool in any CNC Router application. It’s open architectural design accepts G-Code files from any industry standard CAD/CAM software package. The jogging buttons, speed controls and run displays are all visible on the main page. The intuitive single-screen design and functions are easy to use and remember. Customers that are new to automation find the Excitech-USA CNC Interface easy to learn and operate. Most are up and running in less than one day. Customers soon discover that just because the Excitech-USA CNC Interface is easy to use does not mean that it is not a comprehensive CNC program. |

|

Several impressive features include:

|

|

|

Copyright ©

Excitech-USA, Inc. All rights reserved.